Vitrification

Conventional vitrification protocols typically involve cooling rates – up to 12,000°C per minute – combined with stepwise exposure to increasing concentrations of cryoprotectants (CPs), including an equilibration phase to reduce osmotic shock. More recent developments in ultra-rapid vitrification and thawing protocols aim to streamline the process by significantly shortening, or even eliminating, the equilibration phase.

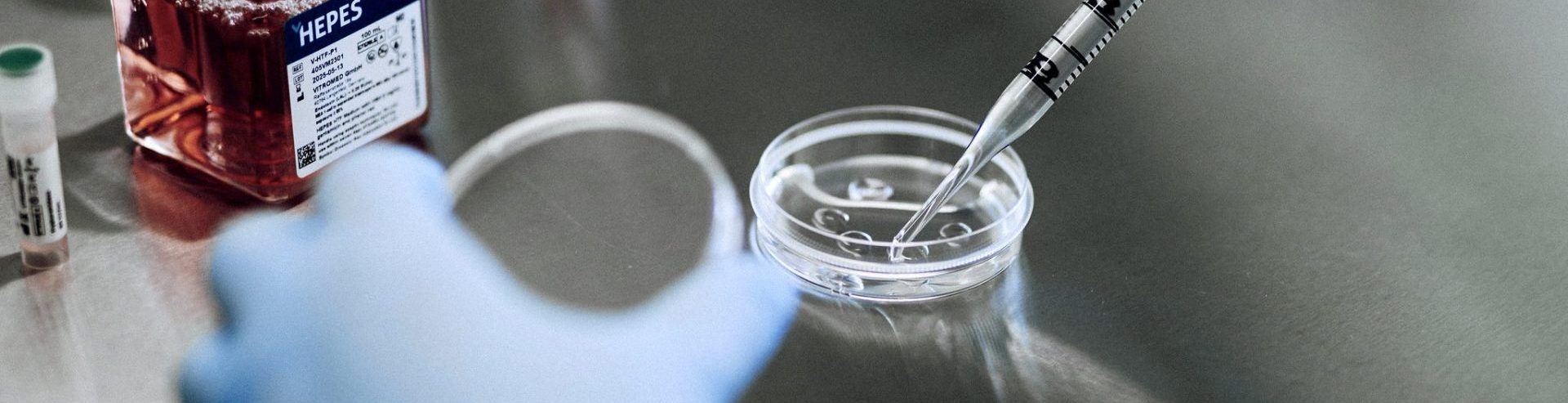

After exposure to final CP concentrations, oocytes or embryos are loaded in minimal volume onto vitrification devices and rapidly plunged into liquid nitrogen (LN₂: −196°C). Open devices allow direct contact with LN₂ for faster cooling and better cell preservation, while closed devices prevent direct contact.